Dry Ice Blasting

Dry ice blasting is known by several names: dry ice blasting, dry ice cleaning, CO2 blasting, dry ice dusting, and even environmentally sustainable cleaning. Dry ice blasting is an efficient and cost-effective way for industries to maximize production capability and quality. Dry ice blasting is similar to sand blasting, plastic bead blasting or soda blasting where media is accelerated in a pressurized air stream to impact a surface to be cleaned or prepared. But that’s where the similarity ends.

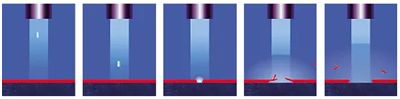

Instead of using hard abrasive media to grind on a surface (and damage it), dry ice blasting uses soft dry ice, accelerated at supersonic speeds, and creates mini-explosions on the surface to lift the undesirable item off the underlying substrate

Dry ice blasting has many unique and superior benefits over traditional blasting media.

• It is a non-abrasive, nonflammable and nonconductive cleaning method

• It is environmentally responsible and contains no secondary contaminants such as solvents or grit media

• It is clean and approved for use in the food industry

• It allows most items to be cleaned in place without time-consuming disassembly

• It can be used without damaging active electrical or mechanical parts or creating fire hazards

• It can be used to remove production residue, release agents, contaminants, paints, oils and bio films

• It can be as gentle as dusting smoke damage from books or as aggressive as removing weld slag from tooling

• It can be used for many general cleaning applications

Dry ice blasting uses compressed air to accelerate frozen carbon dioxide (CO2) “dry ice” pellets to a high velocity. A compressed air supply of 80 PSI/50 scfm can be used in this process. Dry ice pellets can be made on-site or supplied. Pellets are made from food grade carbon dioxide.

Carbon dioxide is a non-poisonous, liquefied gas, which is both inexpensive and easily stored at work sites.