Power Plants

Power Generation

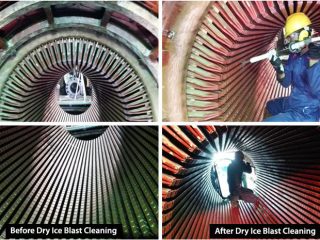

Power Generation professionals know one key to peak performance is clean electrical equipment; however, the demand to keep the equipment running often leads to deferred cleaning and maintenance, reduced efficiency and in some cases, outages caused by flashover. Dry ice blast cleaning provides a non-conductive, environmentally responsible cleaning process that allows equipment to be cleaned in-place, without cool down or disassembly. In addition, the outage time typically needed for cleaning can be reduced up to 65%.

Cleaning with Dry Ice Blasting in the Power Generation Industry Will:

- Reduce catastrophic failures

- Increase Polarization indices

- Improve thermal dissipation

- Eliminate secondary waste

- Reduce outage time by 65%

- Clean in-place, no cool down or disassembly

Proven Power Generation Applications for Dry Ice Blasting Include:

- Turbines

- HRSG (Heat Recovery Steam Generator)

- Compressors & Generators

- Substation Isolators & Bushings

- AC/DC Motor Cleaning

- Circuit Breakers

- Switch Gears

- Transformers

- Rotors Stators

- Insulators

- Armature

- Field Frames

Electrical Equipment & Power Plants

Generators

Dry ice blasting cleans electrical generating equipment, reducing downtime from overheating. Dry ice blasting also allows the units to be cleaned in place without damage to cables and insulation.

Turbines

Dry ice blast cleaning is perfect for turbines. Dry ice blasting is non-abrasive allowing the cleaning of deposits and other foreign materials without distorting the blade.

HRSG (Heat Recovery Steam Generator)

The dry ice does a great job cleaning the first couple rows of tubes. Beyond that it is just simply the force of air pushing the debris through the tubes. Lower pressure blasting can actually pack the debris in the middle of the tubes and increase the back pressure. Our high pressure blasting forcefully blows the debris completely through bundles containing over sixteen rows of tubes.

Electric Motors

Cleaning with dry ice allows electric motors to be cleaned in place, saving time and money through reduced labor and equipment downtime. The dry process means no secondary media waste and minimal clean up. The non-abrasive nature of dry ice cleaning means no damage to small parts.

Small Components

Dry ice blasting requires no solvents to remove surface residue material from small components as they move along the assembly line. The non-abrasive nature of dry ice blasting means no damage to plated surfaces. Dry ice blasting also removes masking wax used in specialized plating processes.

Insulators & Switches

Dry and non-conductive, dry ice blasting uses very dry compressed air and “hot stick” dry ice blasting nozzles to clean energized switch gear. Arc-over-causing dirt is removed with no equipment downtime. Dirt-laden cable trays can be cleaned with dry ice blasting without worrying about solvent fallout or cable damage from cleaning tools.

Cable Ways & Trays

Dry ice blasting is the simplest and quickest way to clean cable trays and ways. Cleaning with dry ice removes accumulated dirt, grit and other foreign materials without damaging the cable insulation or shielding.

Power Plants & Substations

During summer peak electric power loads, power plant operators need all generators working at peak efficiency. Dry ice blasting allows power generation equipment to work at optimal efficiency, potentially preventing catastrophic failure such as flashovers.

Dry ice blasting cleans electrical equipment in place, reducing equipment downtime and the labor cost of disassembling equipment, while minimizing the potential for damage. Since dry ice sublimates, secondary waste cleanup is minimized and no solvent disposal or drying-time is needed.

Blasting Applications

| Electrical | Facility Equipment | Manufacturing | Power Generation | Real Estate | Restoration |

|---|---|---|---|---|---|

| AC/DC Motors | Conveyors | Plastic Molds | Turbine | Escalators | Fire Restoration |

| Electrical Boxes | Conveyor Chains | Industrial Ovens | Substation Isolator | Stairwells | Historic Restoration |

| Circuit Breakers | Cooling Fans | Weld Lines | Bushings | Gum Pollution | Mold Remediation |

| Forklifts | Foundry Molds | Switch Gear | Building Exteriors | Boat Hulls | |

| Fleet Vehicles | Printing Presses | Transformer | Walls | ||

| Pipes and Hoses | Resin Removal | Rotor | Ceilings | ||

| General Equipment | Tank Cleaning | Armature | Graffiti Removal |