Dry Ice Blasting in the Food Industries

Keeping food processing surfaces clean is a production manager’s main concern. Removing leftover food, grease, grime, and other residue from production equipment is critical for preventing bacteria growth and ensuring safe, high quality food products. As sanitation regulations become more stringent, labor costs increase, and the industry becomes more environmentally conscious, food companies are looking for new cleaning processes and solutions.

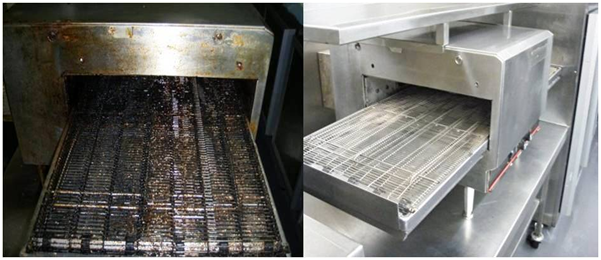

Caked-on dust, flour, grease, and oil, along with baked-on carbon, are some residues that are prevalent—and difficult and costly to remove from baking and production equipment. To ensure product quality, these residues must be removed frequently. Unfortunately, traditional cleaning processes, such as steam, water, and manual scrubbing, are slow, inefficient, and ineffective. Plant managers at a baked goods facility in Chanhassen, Minn., for example, found that it took a three-person maintenance crew nearly nine hours to clean their 30’ x 50’ machines. During that time, the cleaning crew could only remove 80% of the residue; the machine’s small parts and hard-to-reach areas simply could not be cleaned by hand. This scenario is not uncommon.

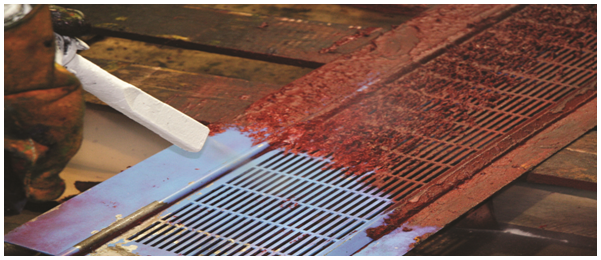

One alternative to conventional cleaning processes used by food companies is dry ice blast cleaning, a process similar in concept to sand or bead blasting. Unlike sand or bead blasting, however, dry ice blast cleaning is not only safe for food processing environments, but also costs less, cleans more efficiently, and is more environmentally responsible.

The food industry is heavily regulated. Some regulations concern water disposal and recycling sanitation issues. Others go as far as detailing the number of hours maintenance crews must devote to cleaning equipment. Any cleaning solution used by a food company must provide optimal cleaning results, while being safe enough to clean surfaces that come into contact with food products. The cleaning method used could impact the taste, cooking, processing, and overall quality of the food product.